Designing mobility: Students create adjustable prostheses for amputees

News

Child amputees in the United States often suffer from residual limb pain and discomfort due to rapid limb growth — a significant challenge in prosthetic development.

JMU Engineering students Parker Agan, Will Bradford, Megan Caulfield, Abby Charleston, Matrix Chen, Jack Nordstrom, Danny Tyra, Emily Vierrether and Jack Zhao embarked on a capstone project with a clear mission: to design a comfortable, well-fitting, below-the-knee prosthesis capable of adjusting in length and volume, ideally growing with a child. This innovative design aims to reduce the need for frequent replacements, easing the financial burden on families.

Under the guidance of Engineering professor Jason Forsyth, the team began extensive research and planning to gain a comprehensive understanding of prosthetic needs. “I allowed them to take the lead while supporting their milestones and assisting them with technical challenges,” Forsyth explained. “They’re engaged, self-driven, self-motivated and hungry for knowledge.”

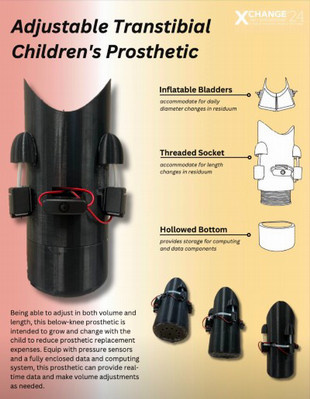

The team divided into three subgroups focused on specific tasks: length adjustment, volume adjustment and computing.

The volume team tackled fluctuations, including leg swelling and minor changes over one to two years. The length adjustment team addressed adaptations, ensuring the prosthesis aligned with the child’s growth.

Charleston noted the lack of adjustable prostheses on the market, particularly for children. “Improper fit of prostheses can cause discomfort, rashes and sometimes open wounds to the skin. These limitations can prevent children with prostheses from running, jumping and playing,” she added.

The computational team developed a system that enables real-time monitoring and adjustment of the prosthesis using sensor data. If a child outgrows their prosthesis, the system automatically sends a notification to make the necessary adjustments.

“We created a mold of a children’s prosthesis and placed fiberglass on top of it to create a more realistic socket,” Zhao said of the prototyping process.

Additionally, the team acquired an adult-sized prosthetic socket for reference and fitted it with plastic bags and a pump to simulate limb changes. This helped the team meet their design requirement and ensure the prosthesis’ functionality.

Over two years, the project evolved into a sophisticated design featuring air bladders to adjust the socket’s internal volume, a screw mechanism for length, and an onboard computing system to collect data on force and pressure within the socket.

“They’re doing something tangible to help people, and that’s always a good feeling,” Forsyth said.

Caufield reflected on the project as a realization of her lifelong interest in prosthetics, combining her passion for engineering with her desire to help others. “Being able to design something that has such a positive impact on someone’s life is exactly what I want to do.”

The project not only met but surpassed the team’s initial goals, leading them to win the 2024 JMU Engineering People’s Choice Award and Best Overall capstone project.

“I am proud to have worked alongside this group — to have accomplished such an impactful project that started as an idea, with the immense help and support of our faculty advisor, Dr. Jason Forsyth, for taking on this project and pushing us to reach our goals,” Vierrether said.

The team’s success is a testament to the JMU Engineering program’s ability to prepare future engineers to make real-world impacts, big or small. As this group of dedicated students moves on, their contributions will undoubtedly continue to resonate, offering new possibilities for children amputees to play, jump, and run — just like their peers.

“We have produced something we are all proud of,” Charleston said.