HAZWOPER is the acronym for HAZardous Waste OPerations and Emergency Response. It refers to the standard developed by the Occupational Safety and Health Administration (OSHA) for the emergency response operations related to releases or substantial threats of releases of hazardous substances.

James Madison University stores and handles over 136,000 gallons of petroleum products in the form of:

- No. 2 fuel (heating) oil

- No. 4 (heating) oil

- diesel fuel

- bio-diesel fuel

- gasoline

- various motor and hydraulic oils

- waste oil

Products are stored on-site in a combination of above ground storage tanks, underground storage tanks, and drums. These products are used in a wide variety of equipment such as vehicles, boilers, generators, gas and diesel powered equipment. Due to the large capacity of stored petroleum products on site, JMU is required to maintain a Spill Prevention, Control, and Countermeasure (SPCC) Plan in accordance with the EPA. This plan dictates a certified HAZWOPER team be designated and on-site to be able to respond to any spills to prevent discharge to any navigable waters.

In the event of a spill or discharge:

Quickly assess the severity of the discharge in terms of quantity and consequences. Notify the HAZWOPER Team via the Work Control Center (568-6101) or JMU Police Department (568-6911) and report the location of the discharge, the type of material discharged, the quantity of material discharged, and any additional information that the Facility Response Coordinator (Dennis Hart) may need. If adequately trained in discharge response, follow the procedure in Section 3.2.3 of the SPCC to contain the discharge. Otherwise, summon additional trained personnel to respond to the discharge. Complete as much of the appropriate Discharge Report Form as possible (this form is found in Appendix B of the SPCC).

Training

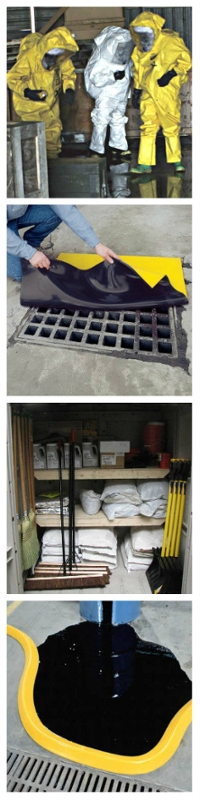

JMU's HAZWOPER team consists of Facilities Management team members from various divisions within the department. In the event of a hazardous waste accident those who handle the hazardous waste must be able to react and control the situation to prevent a more serious situation. In the event of clean-up of waste, handlers must be OSHA HAZWOPER certified. JMU currently has 19 certified team members.

Training includes

- A required OSHA-certified 40-hour class focusing on exposure to hazardous waste.

- An annual OSHA eight-hour refresher course is required for all individuals with HAZWOPER certification.

To receive a HAZWOPER certification by OSHA, an individual must complete a 40-hour course by an OSHA certified training company or association. Training is offered by various universities and community colleges as well as private companies. Online training courses are also offered by licensed software companies.

Even though team members are trained and certified to respond to toxic chemical spills, JMU's HAZWOPER team is currently not equipped to respond to spills of this nature; therefore, the Harrisonburg Fire Department's HAZMAT Team is called to respond to toxic chemical spills.

Procedures

In the event of a spill, JMU has in place multiple spill caddies, drum storage and storage sheds are placed throughout campus.

HAZWOPER storage sheds are set up throughout campus for quick response. HAZWOPER sheds contain clean up equipment, spill kits, spill blocker dikes and various emergency equipment.

Storm drain and spill blocker dikes are used to prevent hazardous waste from entering storm drains.

Mercury spill kits are available in the event of a spill.

Prevention

Drum Storage units are used for containing hazardous materials on campus.

Spill caddies and kits are located on campus and contain various absorbent materials to clean up spills.

In order to prevent mercury from releasing into the environment, Facilities Management has instituted a bulb crushing policy. The bulb crusher has a vacuum with a HEPA, and charcoal filtering system which collects all contaminates from the bulb. The crusher collects bulb particles in a 55 gallon drum and is then picked by JMU Recycling. Only trained employees can operate the bulb crushing machine.

Spiral bulbs are collected in a separate 55 gallon drum and picked up by JMU Recycling and disposed of properly.

Facilities Management maintains a material safety data sheet (SDS) for all chemicals used in the work place. Each shop has a MSDS book which contains information on the chemicals employees handle. Employees need to be familiar with the SDS for each chemical that they work with in order to be able to respond to an emergency situation or to use the chemical properly. Flammable materials are stored in flammable cabinets.